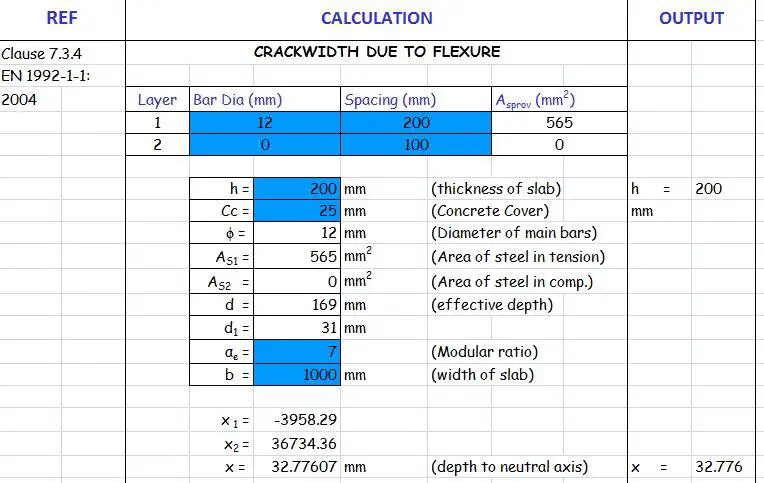

Eurocode 2 part 1-1: Design of concrete structures 7.3 Crack control

The crack width, wk, may be calculated as follows:

Crack width, wk= sr,maxcr where sr,max= Maximum crack spacing = 3.4c + 0.425 (k1k2/p,eff) cr= Crack-inducing strain = Strain between cracks = Mean strain in steel – mean strain in concrete, (cs-cm). Where c = nominal cover, cnom.

| wk = sr,max⋅(εsm - εcm) | (7.8) |

- Crack Width Calculation Spreadsheet - energyfasr Crack-width-check Disclaimer Check Schedule As m Crack width BS 5400 pt 4 C.L. 5.8.8.2 Cnom is the required nominal cover dc is the depth of the concrete in compression (if dc is 0 use BS5400 Pt 4 Eq. Reinforced Concrete Design Spreadsheets - Including Concrete Beam, Slab and Stair Design.

- Feb 17, 2020 Where there is a risk of a calculation giving negative times and you want to display these I would recommend including cells in your spreadsheet which are only used for display and perhaps hide the cells containing the pure numeric values which the spreadsheet is using for its calculations. So going back to your example: In Cell D46 you would have.

- May 22, 2021 Basement Wall Design Spreadsheet Column Load Evaluation Spreadsheet Concrete Creep, Shrinkage Factors and Tensile Strength Calculation Core Wall Design Spreadsheet Crack Width Calculation Spreadsheet Fixed Steel Column Base Design Pad Foundation Design Spreadsheet Pile Cap Design Spreadsheet Post Tensioned Analysis & Design Spreadsheet.

- RCC14 Crack Width.xls. Download Full PDF Package. A short summary of this paper. 37 Full PDFs related to this paper. RCC14 Crack Width.xls. RCC14 Crack Width.xls. R68 CRACK WIDTH CALCULATIONS - FLEXURE - INPUT fcu= 35 N/mm2 fy= 500 N/mm2 Area of reinforcement ' As.

where:

- sr,max

- is the maximum crack spacing

- εsm

- is the mean strain in the reinforcement under the relevant combination of loads, including the effect of imposed deformations and taking into account the effects of tension stiffening

- εcm

- is the mean strain in the concrete between cracks.

| (7.9) |

Crack Width Calculation Spreadsheet 2019

where:

see application for a rectangular section or application for a T-section

with

- Ecm

- the secant modulus of elasticity of concrete

fct,eff = fctm or lower, (fctm(t)), if cracking is expected earlier than 28 days

| = (As + ξ1⋅A'p)/Ac,eff | (7.10) |

with

the adjusted ratio of bond strength taking into account the different diameters of prestressing and reinforcing steel:

the adjusted ratio of bond strength taking into account the different diameters of prestressing and reinforcing steel: | ξ1 = | (7.5) |

Crack Width Calculation Spreadsheet Excel

with

- ξ

- the ratio of bond strength of prestressing and reinforcing steel, according to Table 6.2

- ΦS

- the largest bar diameter of the reinforcing steel

- ΦP

- the diameter or equivalent diameter of prestressing steel:

Φp = 1,6⋅√AP for bundles, where AP is the area of a prestressing steel,

Φp = 1,75⋅Φwire for single 7 wire strands,

Φp = 1,20⋅Φwire for single 3 wire strands, where Φwire is the wire diameter.

kt = 0,6 for short term loading,

kt = 0,4 for long term loading.

• Where the bonded reinforcenlent is fixed at reasonably close centres within the tension zone (spacing ≤ 5(c + Φ/2), cf. Figure 7.2), the maximum crack spacing sr,max may be calculated as follows:

| sr,max = k3c + k1k2k4Φ / ρp,eff | (7.11) |

where:

k1 = 0,8 for high bond bars,

k1 = 1,6 for bars with an effectively plain surface (e.g. prestressing tendons).

k2 = 0,5 for bending,

k2 = 1,0 for pure tension.

Intermediate values of k2 should be used for cases of eccentric tension or for local areas:

| k2 = (ε1 + ε2)/(2ε1) | (7.13) |

where ε1 is the greater and ε2 is the lesser tensile strain at the boundaries of the section considered, assessed on the basis of a cracked section.

• Where the spacing of the bonded reinforcement exceeds 5(c + Φ/2) (cf. Figure 7.2), or where there is no bonded reinforcement within the tension zone, the maximum crack spacing sr,max may be calculated as follows:

| sr,max = 1,3(h - x) | (7.14) |

where:

- h

- is the overall depth of the section (see Figure 7.1)

- x

- is the neutral axis depth of the section (see Figure 7.1).

This application calculates the crack width wk from your inputs. Intermediate results will also be given.

First, change the following option if necessary:

The CivilWeb Crack Width Calculation Excel Sheet analyses a concrete beam to determine the width of any expected cracks in accordance with BS 8110. This analysis is useful where crack widths in concrete beams need to be minimised for either aesthetic or practical reasons. The spreadsheet also includes unique analysis tools which allow the designer to easily optimised the proposed concrete beam design to suit a desired crack width.

The CivilWeb Crack Width Calculation Excel Sheet can be purchased at the bottom of this page for only £20. Alternatively the Crack Width Calculation Excel Sheet is included in the Concrete Beam Design Suite. This suite of spreadsheets includes our Singly Reinforced Concrete Beam, Doubly Reinforced Concrete Beam, T Shaped Concrete Beam and Prestressed Concrete Beam Design Spreadsheets along with our Beam Analysis spreadsheets for a full concrete beam design package. This suite can also be purchased at the bottom of this page for only £30, a saving of over 60%.

Or why not purchase our best value Full Concrete Design Suite. This comprehensive collection of all our concrete design and analysis spreadsheets includes all the tools required for the design of all the most commonly required concrete members including beams, columns, slabs and more. This is our best value spreadsheet bundle and can be purchased at the bottom of this page for only £50, a saving of over 80%.

Crack Width Calculation in Concrete Beams

Concrete is commonly used for the construction of structural beams because it is cost effective, mouldable to any size and shape and provides good durability and fire resistance properties.

Although concrete is relatively strong in compression, it is very weak in tension. Generally concrete will be around ten times stronger in compression than in tension. This is due to the fact that concrete is a composite material made of stone aggregates bonded together with cement. Stone and cement are both strong in compression and are difficult to compress. However the bond between cement and the stone aggregates is much less strong, making concrete relatively easy to pull apart or crack in tension.

When a concrete beam experiences a bending moment from its load and its self-weight, the concrete at the top of the section experiences compressive stresses which the concrete can handle. The bottom of the concrete experiences tensile stresses which usually will be too much for the concrete to accommodate on its own, leading to cracks and failure.

To avoid the failure of the beam, structural steel reinforcement is included at the bottom of the concrete beam which is designed to handle all the compressive stresses. However, before the steel reinforcement can take any of the tensile stress, the concrete around the reinforcement needs to move slightly to transfer the stress into the steel. In order to move, the concrete must crack.

Once the crack has developed, now the steel can accommodate the tensile stress. However as the tensile stress in the steel increases, the steel will start to deform slightly under the tensile load. This will induce further cracking and will start to increase the width of the existing cracks under load. The width of these cracks will depend on the amount of tensile stress in the beam and the amount of steel reinforcement.

It is very difficult or even impossible to design concrete beams which will not crack at all. Hardened concrete is quite brittle and does tend to crack even under its own self weight. Concrete beams often crack even before they are loaded due to shrinkage effects during curing. However these cracks can be very small indeed, microscopic even.

In most cases small cracks in concrete will not be a problem. They can be covered by painting which will conceal cracks until they reach a certain width. However it is not desirable for concrete beams to contain a large number of cracks for aesthetic reasons. Even if the beam is structurally sound it does not inspire confidence and looks problematic for the general public.

Wide cracks in concrete beams can also allow water, salts and other chemicals to percolate through the concrete and reach the steel reinforcement. Steel will not usually corrode when surrounded in concrete but if water and other substances can reach the concrete this upsets the corrosion protection offered by the concrete and will lead to corrosion of the steel. As this continues it will lead to the steel expanding which leads to larger cracks and spalling of the surface, which in turn leads to more corrosion and so on.

CivilWeb Crack Width Calculation Excel Sheet - Inputs

The CivilWeb Crack Width Calculation Excel Sheet calculates the maximum crack width in accordance with the BS 8110 procedure. The designer must input the beam dimensions and concrete properties, the quantity of structural steel reinforcement and the applied bending moment acting on the beam. Then the spreadsheet calculates the maximum crack width to be expected in the tensile zone of the beam.

The CivilWeb Crack Width Calculation Excel Sheet includes unique crack width analysis tools which show the designer at a glance the maximum crack width for differently sized beams and for different reinforcement quantities. This allows the designer to optimise the design of the beam to suit any particular crack width requirements without having to complete time consuming iterative calculations.

CivilWeb Crack Width Calculation Excel Sheet

The CivilWeb Crack Width Calculation Excel Sheet is a handy tool for the calculation of crack widths in concrete beams in accordance with BS 8110. This spreadsheet completes all the calculations instantly and allows the designer to optimise the design of the proposed concrete beam to suit a particular maximum crack width in minutes.

Buy the CivilWeb Crack Width Calculation Excel Sheet now for only £20.

Buy the CivilWeb Concrete Beam Design Suite including a total of 5 different beam design and analysis spreadsheets for only £30.

Or why not buy our best value bundle, the full CivilWeb RCC Design Suite which includes all of our concrete design spreadsheets for only £50, a saving of over 80%.

Download Free Trial Version

To try out a fully functional free trial version of this software, please enter your email address below to sign up to our newsletter.